Giải pháp tự động hóa đã trở thành một xu hướng không thể thiếu trong các ngành công nghiệp hiện đại. Với sự phát triển mạnh mẽ của công nghệ, tự động hóa giúp các doanh nghiệp tối ưu hóa quy trình sản xuất, tiết kiệm chi phí, và tăng cường hiệu suất. Trong bài viết này, chúng ta sẽ tìm hiểu về giải pháp tự động hóa, các loại hình phổ biến, lợi ích và cách triển khai hiệu quả trong doanh nghiệp.

What is automation?

Automation is the process of using technology, machinery and software systems to replace or assist humans in performing repetitive, high-precision or labor-intensive tasks. The goal of automation is to reduce production time. Increase productivity and ensure product quality.

Benefits of automation solutions

Enhanced safety

- Minimize the risk of occupational accidents: Dangerous and toxic jobs such as working at high temperatures and exposure to toxic chemicals can be assigned to robots, minimizing the risk of accidents for workers.

- Safer Work Environment: Automation eliminates manual labor. Reduces worker stress, creating a safer and healthier work environment.

- For example, in the automotive industry, welding robots can perform welding operations at high temperatures, reducing the risk of burns to workers.

Increased flexibility

- Respond quickly to orders: Flexible automation systems can be easily adjusted to produce different products in small quantities, meeting diverse market needs.

- Product Customization: Automation allows businesses to easily customize products according to customer requirements. Create more unique and competitive products.

- For example, in the electronics manufacturing industry, automated production lines can be quickly changed to produce new phone models with different configurations.

Data collection and analysis

- Manufacturing Data Management: Automation systems collect large amounts of data about the manufacturing process. Helps businesses track and analyze manufacturing performance.

- Continuous improvement: Based on the collected data, businesses can identify weaknesses in the production process and propose improvement solutions.

- For example: In the food manufacturing industry. IoT sensors can collect data on temperature. Humidity during storage. Helps ensure product quality and detect damage problems early.

Enhance competitiveness

- Reduced production costs: Automation helps reduce production costs. Helps businesses gain a competitive advantage in terms of price.

- Improve product quality: Higher quality products will help businesses gain customer trust and create a competitive advantage in the market.

- Responding to market needs: Automation helps businesses quickly adapt to market changes and meet diverse customer needs.

Other factors to consider when choosing an automation solution

Initial Investment

- Cost-benefit analysis: Businesses need to conduct a thorough analysis to compare the initial investment costs with the long-term benefits.

- Hidden costs: In addition to the cost of purchasing equipment. There are also costs such as installation, operation, maintenance, staff training, etc.

- Payback period: Estimate of the time required to recover the initial investment.

- Financial sources: Survey possible financial sources such as bank loans, financial leasing, etc.

Automation Solutions – Human Resource Training

- Skills Needs: Clearly identify the skills required for the automation system operations and maintenance team.

- Choose the training format: Internal training, external training, a combination of both.

- Training Costs: Estimate costs for training courses and related activities.

- Develop a long-term training plan: Ensure your staff is always updated with new knowledge and skills.

Changes in work processes and corporate culture

- Changing employee roles: Some jobs may be replaced by machines. Requiring businesses to re-arrange jobs for employees.

- Improve soft skills: Employees need to be trained in soft skills such as teamwork, problem solving, and creativity to adapt to the new working environment.

- Build a culture of learning and innovation: Encourage employees to proactively learn and adopt new technologies.

- Build effective information and communication systems: Help employees understand the transition process and answer questions.

Popular automation solutions

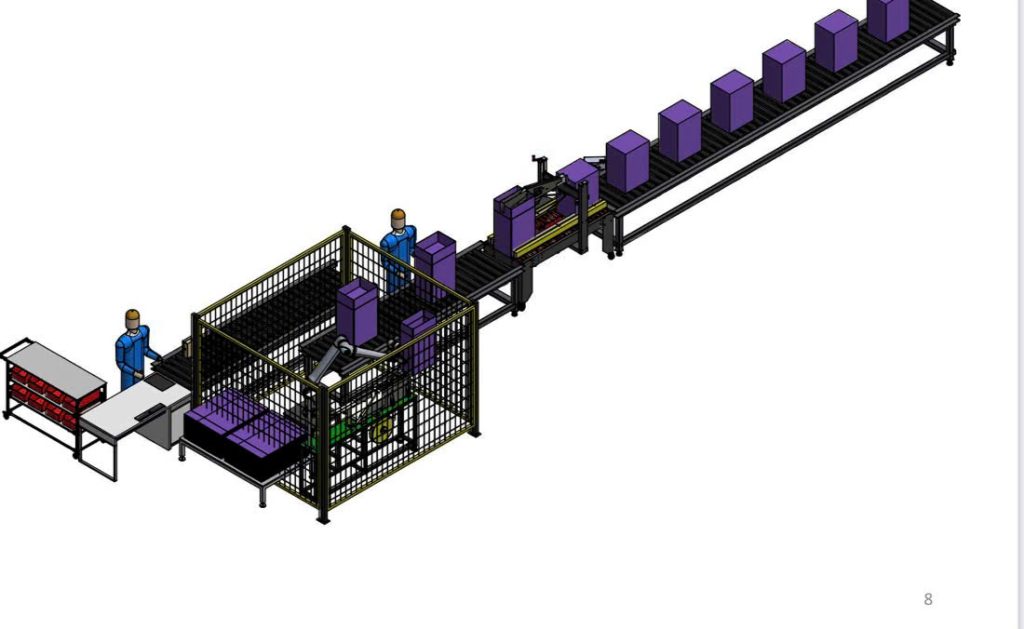

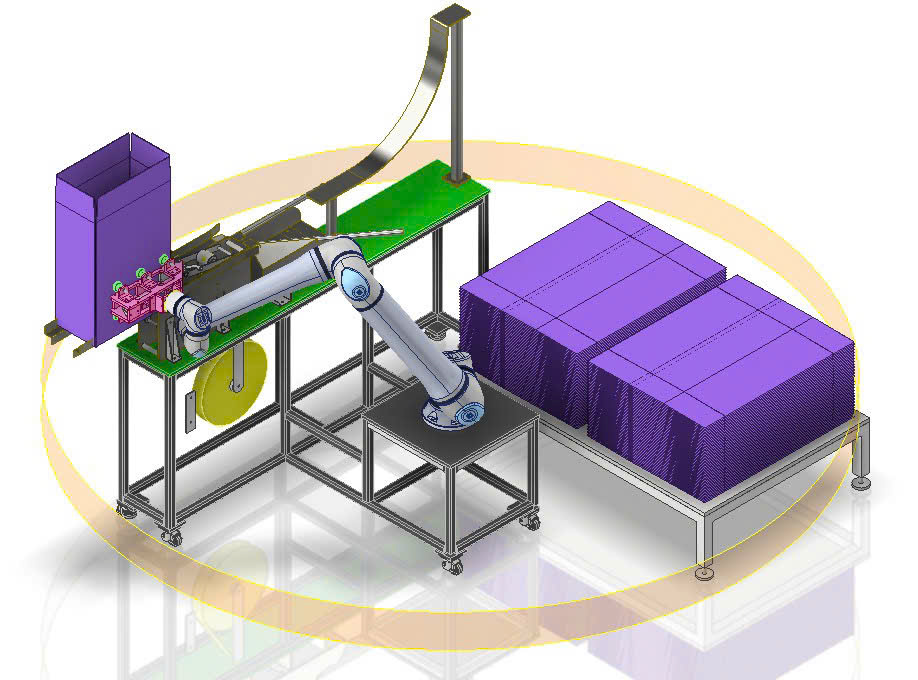

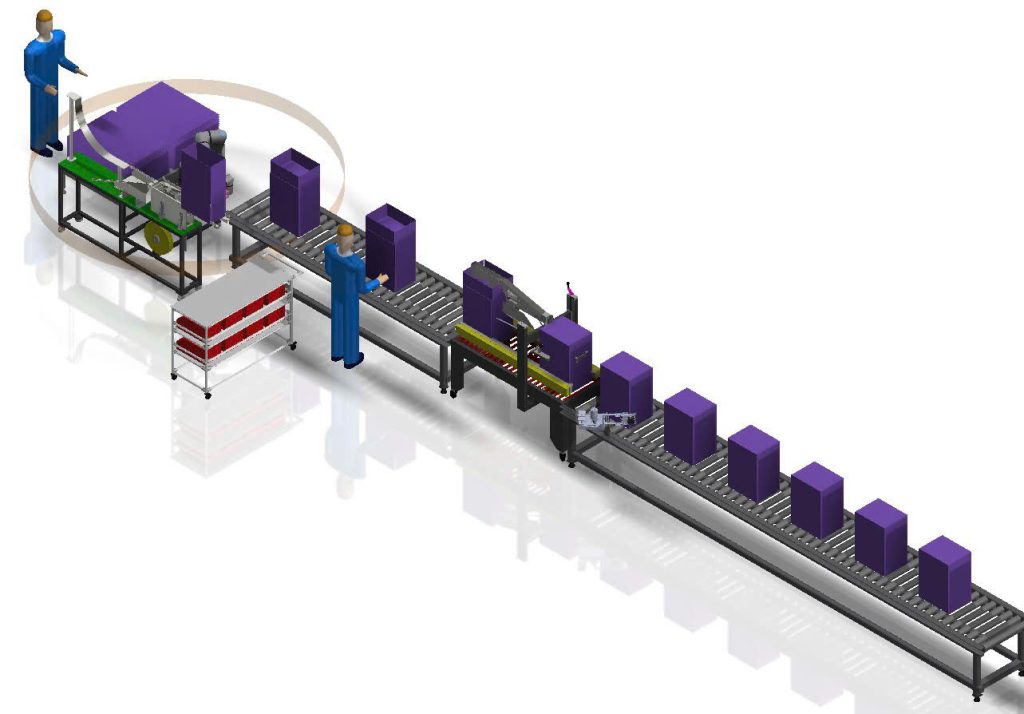

- Industrial robots are widely used in industries such as automotive, electronics, pharmaceuticals and food. Robots are capable of performing repetitive tasks such as welding, assembly, product testing and packaging.

- SCADA is a remote control and monitoring system. It helps manage the entire production process through sensors and control software. SCADA collects data, provides analysis and early warning when problems occur.

- IoT technology in manufacturing allows machines and devices to connect with each other and exchange data. IoT devices mounted on machines will collect data in real time and send it to the central system for analysis.

- AI is playing an increasingly important role in automation. It helps analyze big data and predict manufacturing trends. AI can automatically optimize manufacturing processes and make suggestions for improvements.

- AGV is an autonomous vehicle system used to transport goods in factories without human intervention. AGV is capable of moving along pre-programmed routes and avoiding collisions through sensors.