The machinery system in the industry always plays a key role and is the backbone for factories to operate and produce products. Since the birth of the mechanical industry, the machinery system has always been developed and improved continuously over time.

From the most primitive conveyor belt systems or chains using human power or “rice-powered robots” to more developed ones using electrical systems and chains, but still requiring a lot of human intervention. And until now, when the 4.0 industrial revolution has been developing very strongly, automation companies have developed many different automation solutions to serve many industries in life and especially the manufacturing industry.

What is an automatic system?

The automatic machine system has actually been researched and developed for a long time, with many different methods, people have always thought of machines that operate without human intervention, a completely automatic operating mechanism. And after many years as well as going through many reforms, the progress in science and technology has now brought us to a new era - the era of automation.

Automation application and development can be applied in many different industries, but the most necessary activities are still for the manufacturing industry, processing or manufacturing components, molds, metal products, mechanical processing, etc.

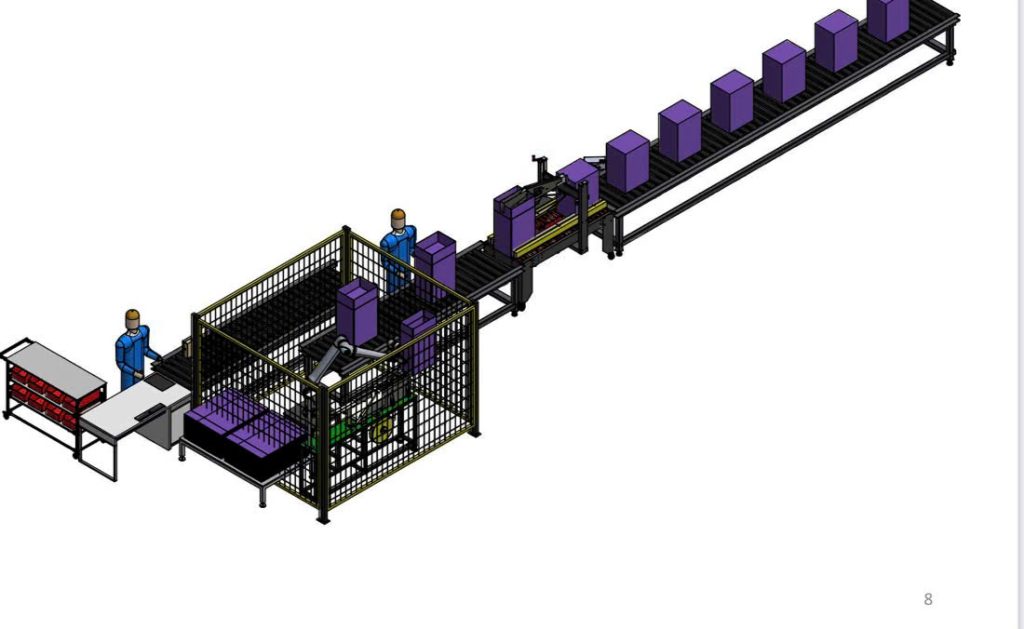

Nowadays, wherever we look or in any factory, we can see machinery systems designed and placed in the factories in the most suitable way.

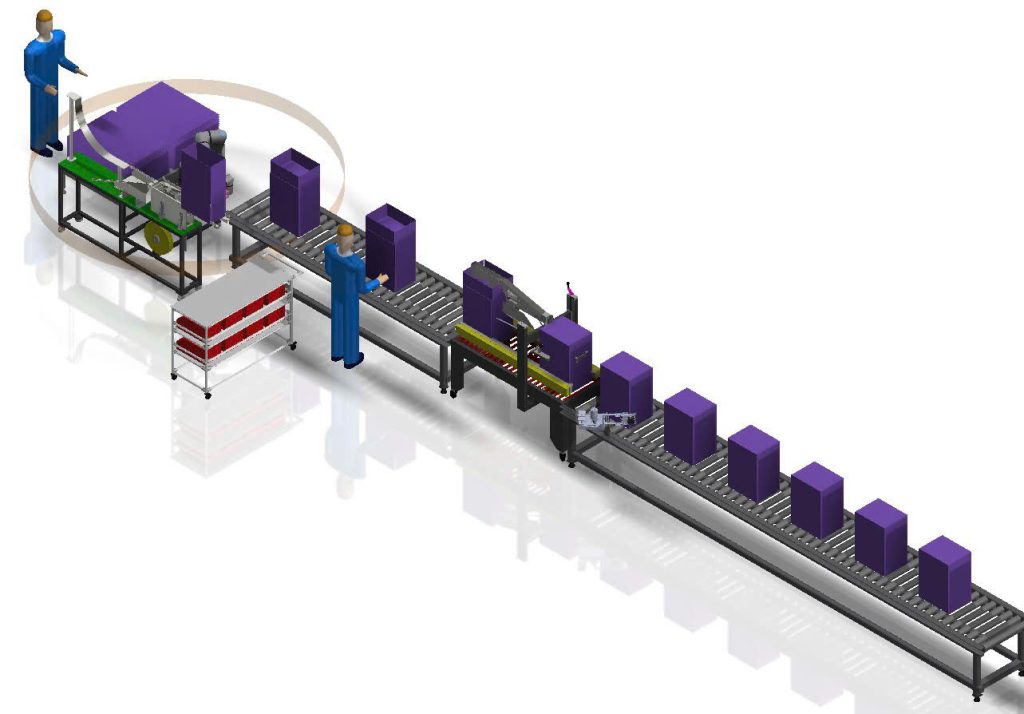

Today's industrial machinery systems are all integrated with automation systems. Depending on the needs of the manufacturing plants, the production line can range from the most rudimentary to the most complex, or in addition, partial and full automation can be applied to the production lines.

Application of automatic machine system

Depending on the needs of the factory or business, the implementation of automation lines is also different. Some of the machine system applications that can be applied are as follows:

- In component manufacturing factories, the implementation of an automated production line system helps to classify and package components more proactively and productively because component products are mainly very small and numerous. If implemented manually, it will not bring work efficiency and cause boredom for workers.

- Food and beverage factories, etc., when applying automatic production lines, will help disinfect and sterilize more thoroughly, limiting human contact with food.

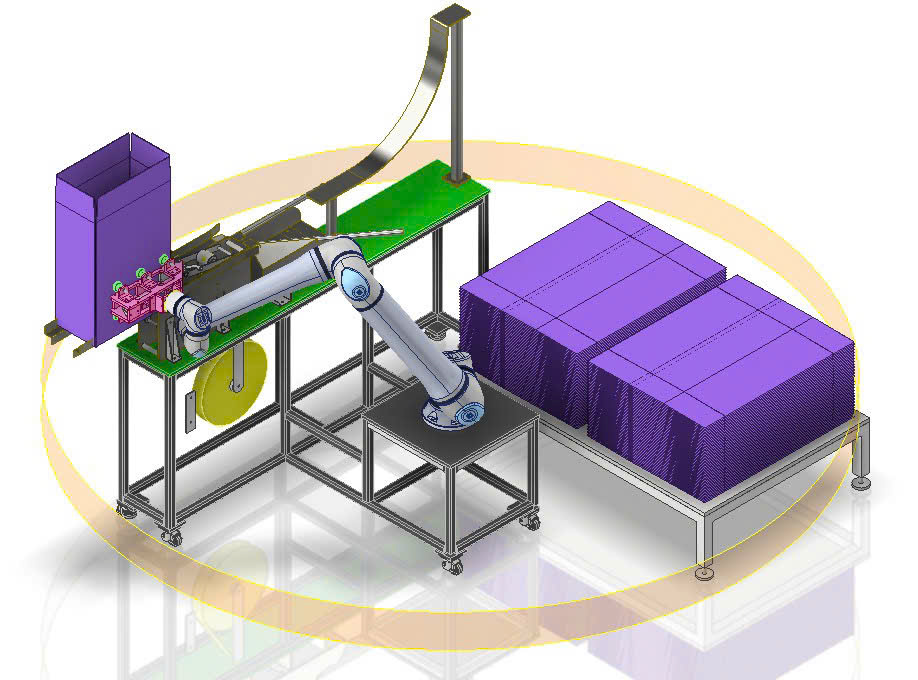

- Mechanical processing factories, when applying automation systems, will help processing become more precise, increasing the accuracy of products.

- Manufacturing and assembly plants: deploy assembly quickly and automatically, achieving the highest level of precision coupling efficiency, for installation on heavy or dangerous equipment also helps ensure labor safety for people.

- In addition to the above applications, the application of automation systems is also the goal of many industrial companies today. On the current development of industry 4.0, the creation of smart factories is a common trend of many large enterprises because of the values they bring.

Conclude

Production line automation is an inevitable trend in the development of today's industry. Depending on human creativity, the automation system is applied to what extent. And besides, the cost is also a matter of concern, but in the long run, the implementation of automation systems will be better.